Executive summary

Dive into the transformative world of automation in the manufacturing landscape, where efficiency blends with innovation. This comprehensive blog explains the essence of automation within the industry, shedding light on the pivotal role of process automation, the evolution of manufacturing processes, and the broad spectrum of benefits it brings. From enhancing operational workflows to revolutionizing customer service and beyond, discover the indispensable need for automation in today’s manufacturing domain. Equip your business with insights on leveraging cutting-edge automation technologies to stay ahead in the competitive market.

Walk into a modern factory today, and you’ll find a place where machines work alongside humans, not just with cold efficiency but with a precision that seems almost like art. Stepping onto the manufacturing floor today reveals a scene straight out of the future we once imagined. Machines and technology have woven into the fabric of production processes so seamlessly it’s hard to believe there was a time when they weren’t the norm. This transformation, driven by automation, marks a new era in manufacturing—a leap toward unmatched precision, efficiency, and speed.

Gone are the days of lengthy assembly lines and manual labor dominating the production narrative. Instead, automation has ushered in a new age of manufacturing intelligence, where automated processes work alongside humans, not as replacements but as partners. They enhance the capabilities of the workforce rather than diminishing them. This partnership promises a boost in productivity and a revolution in the way we perceive manufacturing jobs and processes.

Related must-reads:

- Customer service automation – A full guide

- 10 Types of customer service you should know

- Customer service software: How to select the best one

- Good customer service: Ways to deliver [+10 Examples]

What is automation in manufacturing?

Imagine walking into a factory where machines and software systems are the maestros, conducting an orchestra of production activities with precision and grace. It is the essence of automation in manufacturing. It is a symphony of technology-driven processes that streamline production, enhance efficiency, and open new horizons of productivity.

Automation represents the integration of sophisticated machinery and advanced software to carry out manufacturing tasks previously dependent on human labor. This shift is not merely about replacing manual effort but about augmenting and elevating the capabilities of the manufacturing sector to unprecedented levels.

In recent times, the push towards automation has gained momentum. It is fueled by technological advancements and a redefined understanding of its potential. The statistics are telling – with the International Federation of Robotics reporting a significant increase (3.5 million) in industrial robots worldwide. It reflects a growing adoption of automation technologies across the manufacturing landscape. This surge is a strategic move to address the challenges of modern manufacturing. It includes everything from navigating supply chain complexities to optimizing production efficiency in a labor-constrained market.

Automation has become a cornerstone in manufacturing. It is revolutionizing how tasks are approached—from intricate assembly operations to meticulous inspections, alongside the management of inventories and the orchestration of production plans. As we witness a transition from machines dedicated to singular tasks to advanced, intelligent systems with the versatility to tackle a broad spectrum of activities, automation heralds a new era in manufacturing.

This shift is strategic, with an overwhelming 76% of manufacturers now viewing automation as crucial for bolstering productivity and propelling growth. In embracing automation, the manufacturing sector is committing to a fundamental transformation, positioning itself at the forefront of innovation and operational excellence.

Why are manufacturing industries looking to automation?

Manufacturing sectors are increasingly adopting automation, recognizing its potential to tackle current industrial challenges and seize new opportunities. The shift towards automation equips businesses to meet today’s market demands more effectively. It offers enhanced operational efficiency, quality, and adaptability.

Here’s why the trend toward automation is gaining momentum among manufacturers.

1. Streamlining operations: In the quest for efficiency, manufacturing sectors are turning to automation to refine their processes and cut down on inefficiencies. Automation introduces precision and consistency, enabling increased production rates while reducing time and resource wastage. For instance, automated software systems can optimize production schedules and inventory management. It ensures a continuous production cycle without the limitations of human labor schedules.

2. Consistency and quality enhancement: The hallmark of high-quality manufacturing lies in consistency. Automation, through software and advanced monitoring systems, minimizes human error. It ensures products meet the same high standards every time. It boosts consumer confidence and also strengthens brand loyalty.

3. Adaptability and market responsiveness: Automation’s agility facilitates rapid setup for new product lines. It allows manufacturers to swiftly respond to changing market demands and consumer preferences. Systems like Yellow.ai’s automated customer service can quickly adapt to provide support for new products or services. As a result, automation enhances customer satisfaction and competitive edge.

4. Navigating skilled labor shortages: Automation presents a solution to the skilled labor gap, especially in regions where such labor is in short supply. Companies can maintain productivity levels by automating routine tasks without competing for scarce labor resources. That ensures businesses focus their human expertise on the most needed areas.

5. Cost management: The initial investment in automation might be substantial, but the long-term benefits (labor cost savings, minimized waste, and heightened productivity) justify the expenditure for many manufacturers. Software automation, like process optimization tools, significantly lowers operational costs over time. They also provide a sustainable economic advantage.

The benefits of using automation in manufacturing

The relentless force of automation drives the current revolution in modern manufacturing. It is a transformative power that reshapes every corner of the manufacturing floor. The adoption of automation technologies is a strategic shift towards more innovative, more resilient manufacturing practices. Here are some of the key benefits of automation in manufacturing.

1. Improving operations

The quest for operational excellence is a never-ending journey for manufacturers. Automation offers the required efficiency. It drastically reduces the time and resources needed for various manufacturing processes. By automating repetitive tasks, businesses can allocate human resources to more strategic, value-adding activities. That will significantly boost overall productivity.

Imagine a scenario where automated systems now execute a once time-consuming assembly process flawlessly. It cuts production time in half and doubles output without sacrificing quality. This leap in operational efficiency bolsters production capacities and also enhances competitiveness in a fast-paced market.

2. Handling customer service efficiently

Customer service is the battleground where business wars are won or lost today. Automation introduces chatbots and AI-driven support systems that ensure customers receive instant, accurate responses to their inquiries anytime and anywhere. This seamless service experience strengthens customer loyalty and brand reputation.

For instance, a manufacturer might implement an AI chatbot that can instantly provide detailed product information or order status updates. This simple move will transform customer service from a potential bottleneck into a smooth, satisfying experience.

3. Providing an interactive platform

Automation transforms passive customer interactions into dynamic, engaging dialogues. Through interactive platforms powered by AI, businesses can offer personalized recommendations, guide users through complex catalogs, and create a more engaging shopping experience. Besides enhancing customer satisfaction, it also drives higher conversion rates.

Picture an online platform where customers can interact with a virtual assistant that helps them choose the perfect product based on their specific needs and preferences. It can make every interaction an opportunity to delight and engage.

4. Market content through online channels

The digital marketplace is vast and noisy, but automation gives businesses a megaphone. By leveraging automated marketing tools, companies can deliver targeted content, promotions, and updates directly to their audience. That allows businesses to ensure maximum visibility and engagement. An example of this could be an automated email campaign that sends personalized offers to customers based on their purchase history. It will significantly increase the likelihood of repeat business.

5. Improving organizational efficiency

Automation extends its benefits beyond the manufacturing floor. It streamlines administrative and back-office operations. Automation introduces systems that manage inventories, track shipments, and monitor performance metrics in real-time. As a result, it paves the way for a leaner, more efficient organization.

For instance, a manufacturer might use an automated system to predict inventory needs. It will allow them to avoid overproduction or stockouts and ensure that resources are utilized optimally.

6. Easy access to knowledge and databases

We cannot deny the fact that we are already in an information-driven world. Here, knowledge is power. Automation provides employees and customers alike with instant access to vast databases of information. This information can range from technical specifications to troubleshooting guides. This democratization of knowledge speeds up decision-making processes and also empowers customers to make informed choices. As a result, it enhances their overall experience with the brand.

7. Perform HR-related tasks

The human resources department is the backbone of any organization, and automation offers tools to streamline HR tasks. These HR tasks range from recruitment to payroll. Automated systems can handle routine inquiries, manage employee records, and even assist in the hiring process. It allows HR professionals to focus on strategic initiatives that enhance workplace culture and employee engagement.

Automation use cases in the manufacturing industry

Automation stands as the cornerstone of industrial evolution in today’s era. Do not mistake it only for robots taking over the production line. In fact, automation is about harnessing the power of technology to make manufacturing more intelligent, more efficient, and infinitely more adaptable. Let us explore some use cases of automation in manufacturing.

1. Supplies and inventory check

The backbone of any manufacturing operation is its supply chain. Automation introduces unparalleled precision in managing supplies and inventory. It ensures that materials are tracked, stocked, and utilized with maximum efficiency. Through the integration of advanced software systems, manufacturers can monitor inventory levels in real time, predict supply needs, and automate ordering processes.

Consider a scenario where a manufacturer utilizes automation for inventory management. This system alerts the team about low stock levels and also automatically places orders with suppliers. That ensures a seamless production flow. This level of automation reduces downtime, minimizes the risk of overstocking or stockouts, and significantly cuts down waste. As a result, automation makes the manufacturing process more sustainable and cost-effective.

Implementation tips:

- Integrate inventory management software with your existing ERP system for real-time tracking.

- Use data analytics to predict supply needs and automate reordering processes.

- Train your team on the software to maximize its utility and ensure smooth operation.

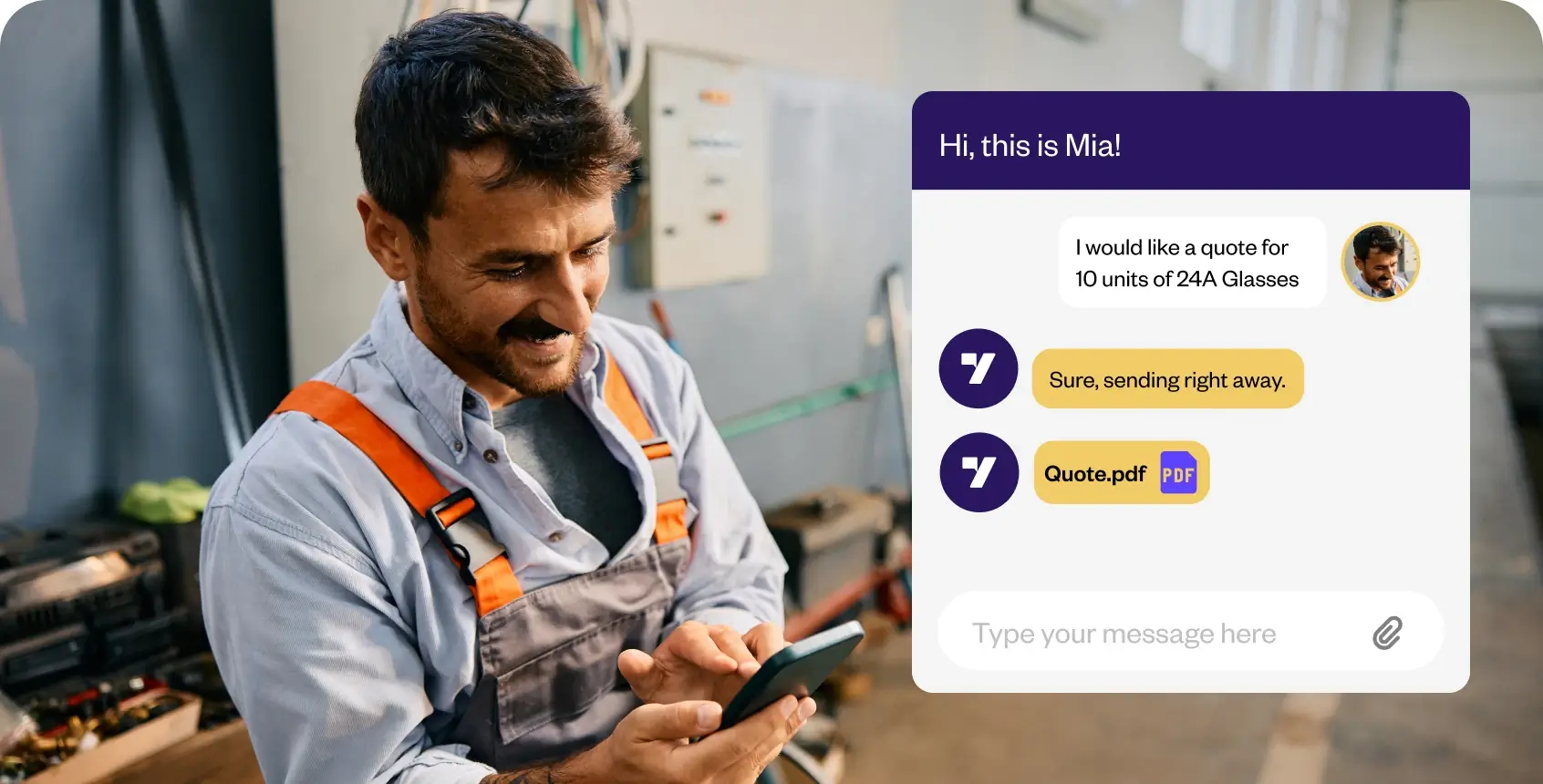

2. Automating customer support

Automation bridges the gap between manufacturers and their clients. By deploying AI-powered chatbots, companies can offer 24/7 customer support, handling inquiries, service requests, and complaints with efficiency and ease. Besides enhancing customer satisfaction, it also frees up human agents to tackle more complex issues.

For instance, a manufacturing firm introduces a chatbot capable of handling standard customer inquiries about product specifications, order status, and troubleshooting. It will lead to a noticeable decrease in response times and a significant improvement in customer satisfaction ratings. The chatbot seamlessly hands off to a human agent for complex issues, ensuring a smooth customer experience.

Implementation tips:

- Choose a chatbot platform that can be easily integrated with your customer service software.

- Regularly update the chatbot’s knowledge base to cover a wide range of inquiries.

- Set up a seamless handoff process for human agents for complex issues.

3. Easy handling of floor queries

Manufacturing floors are busy environments where quick access to information can significantly enhance productivity. Automation in the form of AI assistants can provide instant answers to operational queries. These queries may range from machine status to production schedules. Such quick answers to queries can improve the flow of information across the factory floor.

Consider the example of an automotive manufacturer. The company has implemented an AI assistant that is accessible to all floor workers via mobile devices. Workers can quickly inquire about machine availability, maintenance schedules, or production targets, receiving instant responses. It reduces downtime and improves the overall efficiency of the production line.

Implementation tips:

- Develop a user-friendly interface for your AI assistant that is accessible from various devices.

- Ensure the AI assistant is integrated with your production management system for real-time information.

- Train your staff on how to use the AI assistant to enhance their productivity.

4. Updates and delivery notifications

Staying updated on the progress of manufacturing orders and delivery schedules is crucial for both manufacturers and their clients. Automation enables real-time notifications and updates. As a result, it keeps all stakeholders informed and aligned.

For example, a furniture manufacturing company uses an automated system to send updates to clients about their order status, from production to delivery. Clients appreciate the transparency and reliability, leading to increased trust and repeat business.

Implementation tips:

- Implement a system that automatically updates clients about their order status via email or SMS.

- Ensure your delivery notification system is integrated with your logistics and supply chain operations for accurate information.

- Customize the frequency and type of notifications based on client preferences.

5. Product recommendation

With a vast array of products, guiding customers to the right choice can be a challenge. Automation, through intelligent algorithms, can analyze customer preferences and past purchases to recommend the most suitable products.

For instance, a consumer electronics manufacturer uses a recommendation engine on its website. When customers browse, the system suggests products based on their browsing history and purchase patterns. It will increase sales and enhance the customer shopping experience.

Implementation tips

- Leverage machine learning algorithms to refine product recommendations over time.

- Integrate the recommendation system with your online platforms for a seamless customer experience.

- Collect and analyze customer feedback to continuously improve the recommendation accuracy.

Why your manufacturing operation needs an AI chatbot

For businesses in today’s manufacturing world, the question isn’t if you should adopt AI technology but rather how quickly you can do it. AI chatbots are a pivotal shift in how manufacturers interact with their customers, offering immediate, intelligent responses to inquiries around the clock. These digital assistants can handle a multitude of tasks, from answering product questions to providing order updates. It allows human agents to focus on more complex customer needs.

Why, then, do you need an AI chatbot?

- AI chatbots drastically improve customer service efficiency, offering instant responses to common questions and freeing up human agents for more nuanced interactions.

- AI chatbots are invaluable for gathering customer insights and analyzing queries and interactions to help you better understand your customer base.

- Most importantly, AI chatbots are scalable. They can handle a surge in inquiries without the need for additional human resources. It will ensure that your customer service quality doesn’t dip during peak times.

How Yellow.ai can help you with manufacturing automation solutions?

Yellow.ai heroes innovation in the automation landscape. With our cutting-edge AI technology, Yellow.ai offers manufacturing businesses the tools they need to automate complex processes, enhance customer interaction, and streamline operations. With our advanced and innovative products, services, and solutions, we have been helping various businesses from different sectors automate solutions, especially customer service and support. A few notable deliverables are Yellow.ai Dynamic Automation Platform or DAP, conversational service cloud, conversational AI marketing, and AI analytics.

Thanks to our Dynamic AI Agents, both industry agnostic and specialists, you can automate cross-channel in minutes with over 97% intent accuracy. We handle over 2 billion interactions per quarter like pros. All kinds of businesses may make use of our pre-built and bespoke integrations. Customers and vendors may utilize Yellow.ai generative AI-powered DAP, which powers manufacturing firms around the clock. It allows for the optimization of support operations while reducing expenses.

Here are some standout features:

Dynamic AI agents: Experts in every field, including manufacturing, our active AI agents are here to help. Suitable for worldwide, large-scale organizations, this conversational AI automation is secure, versatile, and accurate.

Intelligent chatbots: Yellow.ai’s AI-powered chatbots can handle a wide range of tasks 24/7. These tasks range from customer queries to order updates. It ensures constant support without increasing the human agent workload.

Natural language processing (NLP): With advanced NLP, Yellow.ai chatbots understand and respond to customer inquiries conversationally. It improves the customer experience significantly.

Automation of routine tasks: Yellow.ai automates repetitive tasks like scheduling, inventory inquiries, and customer feedback collection. That allows human agents to focus on complex problem-solving.

Multilingual support: Catering to a global audience, Yellow.ai’s chatbots can communicate in over 135 languages and dialects. It breaks down barriers and expands your market reach.

Omnichannel integration: Whether your customers prefer contacting you via website, social media, or phone, Yellow.ai provides a seamless experience across all platforms.

Customizable AI solutions: Tailor Yellow.ai’s AI solutions to fit your specific manufacturing processes and customer service needs. It will ensure a perfect alignment with your operational goals.

Continuous feedback tracking and practical insights: Our platform can evaluate client interactions, research findings, and feedback if you want to know how well your business is doing. This data-driven approach is essential for consistently improving customer assistance tactics and keeping standards high.

Advanced analytics: Gain insights into customer behavior, chatbot interactions, and process efficiencies with Yellow.ai’s comprehensive analytics. It will enable informed decision-making.

User-friendly interface: Easy to set up and integrate, Yellow.ai doesn’t require extensive technical knowledge. That makes it accessible for businesses of all sizes.

So, are you ready to transform your manufacturing operations with automation? Book a demo with Yellow.ai today and see firsthand how our futuristic, revolutionary automation and holistic AI solutions can revolutionize your business.

The final thoughts

The landscape of manufacturing is undergoing a transformative revolution. Here, artificial intelligence (AI) and automation emerge not merely as trends but as foundational pillars reshaping production and customer engagement. The implementation of advanced solutions like those offered by Yellow.ai marks a pivotal stride toward a future where operational efficiency, customized experiences, and heightened customer satisfaction are achieved with unprecedented ease.

For manufacturers poised to embrace this evolution, the journey promises to align with the industry’s pace and redefine it. AI ushers in a new dawn for manufacturing, illuminating a path where innovation flourishes and customer contentment becomes the standard. The moment to seize this future is now, embarking on a path illuminated by AI’s potential.